Research

Dissertation work

Sustainable inks for transistors

We investigated water-based inks with minimal post-processing requirements. We explored AuNP and PtNP contacts, revealing water-based inks do not degrade performance [1]. To achieve functional CNT channels, we used intermittent rinsing with water [11]. Finally, we studied crystalline nanocellulose (CNC), providing insights into its performance as a degradable ionic dielectric and the effect of nanocellulose form and surface groups on transistor performance [13].

3D microstructures for sensors

We employed aerosol jet printing to create conductive 3D graphene microstructures using water as the only solvent and without any post-print processing. Adding pillars to the humidity sensor degraded performance, contrary to past reports, whereas trusses improved sensitivity by adding a parallel conduction path to the sensing surface [7].

Capillary flow printing: sustainable + scalable transistors

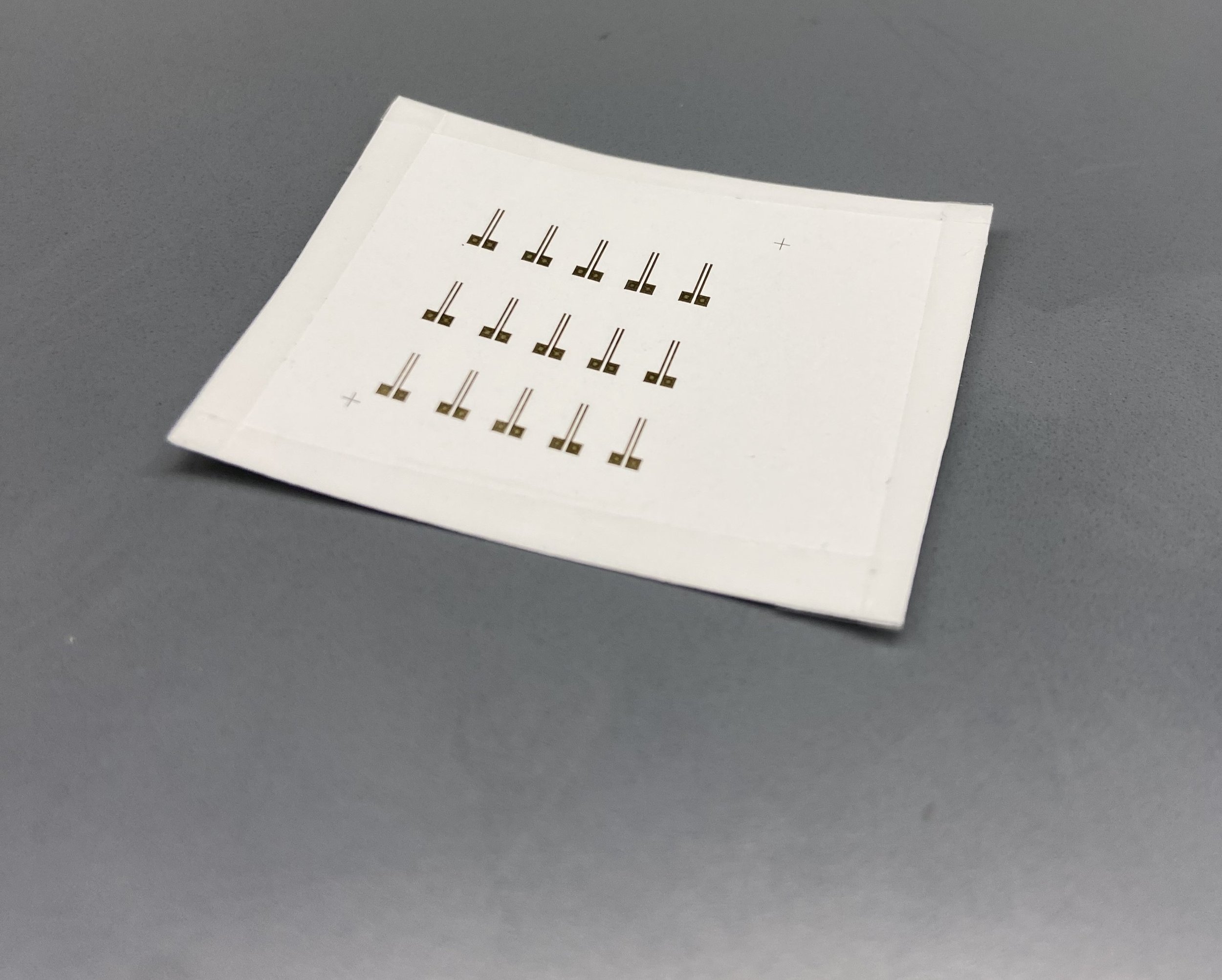

We used a capillary flow printer to realize submicron channels for fully printed carbon nanotube transistors without using any chemical modification on Kapton, a flexible substrate, reducing process waste. The printed devices are competitive with SOTA TFTs for display backplanes with a shorter channel length and on a flexible substrate [2].

Future Work

Solution-Resistant Sustainable Printed Materials

Creating solvent-resistance printed electronics to enable applications such as:

Health + Environmental + Food monitoring

Underwater electronics (on boats, submarines, AUVs, even seals….)

Transportation vehicles

In window displays, antennas, and heaters

Tire pressure and lidar sensors

Printed On-Chip Microelectronics for Processing and Data Storage

Printing scaled logic and memory devices and arrays improve the mechanical robustness over hybrid devices and finally realize printed active electrical components for:

Wearable electronics and sensors (for humans, animals, plants, etc.)

Flexible displays (i.e. printed display backplanes)

Smart RFID tags for improved hardware security

Space Electronics with Printed Materials

Printed materials are ideal for space - lightweight, thin, often rad-hard, and replacements may be created in-flight. Some applications of printed electronics in space include:

Displays and sensors for health and environmental monitoring

Replace general electrical components with lightweight films

Publications

1. B. N. Smith, N. Chen, J. L. Doherty, T. Varghese, D. Estrada, and A. D. Franklin, “Sustainable Print Processes for High Metal Work Function Contacts to CNT-TFTs,” (in preparation).

2. B. N. Smith*, F. M. Albarghouthi*, J. L. Doherty, X. Pei, Q. Macfarlane, M. Salfity, D. Badia, M. Pascual, P. Boncenne, N. Bigan, A. M’Barki, and A. D. Franklin, “Capillary Flow Printing of Submicron Carbon Nanotube Transistors,” (in review, Nature Electronics). https://doi.org/10.48550/arXiv.2406.03602

3. J. L. Doherty, Y. Zhang, B. N. Smith, H. A. Hobbie, I. Kymissis, and A. D. Franklin, “Liquid Crystal Displays with Printed Carbon-based Recyclable Transistor Backplanes,” (in press, IEEE EDL).

4. H. A. Hobbie, J. L. Doherty, B. N. Smith, P. Maccarini, and A. D. Franklin “Conformal printed electronics on flexible substrates and inflatable catheters using lathe-based aerosol jet printing,” npj Flexible Electronics, vol. 8, pp. 54, 2024. https://doi.org/10.1038/s41528-024-00340-0

5. F. M. Albarghouthi, B. N. Smith, and A. D. Franklin, “Printable FET Biosensors based on Carbon Nanotubes” in “Roadmap on printable Electronic Materials for Sensing,” IOP Nano Futures, vol. 8, pp. 032001. https://doi.org/10.1088/2399-1984/ad36ff

6. F. M. Albarghouthi, D. Semeniak, I. Khanani, J. L. Doherty, B. N. Smith, M. Salfity, Q. Macfarlane, A. Karappur, S. G. Noyce, N. X. Williams, D. Y. Joh, J. B. Andrews, A. Chilkoti, and A. D. Franklin, “Addressing Signal Drift and Screening for Detection of Biomarkers with Carbon Nanotube Transistors,” ACS Nano, (in press). https://doi.org/10.1021/acsnano.3c11679

7. B. N. Smith, P. Ballentine, J. L. Doherty, R. Wence, H. A. Hobbie, N. X. Williams, and A. D. Franklin, “Aerosol Jet Printing Conductive 3D Microstructures from Graphene without Post-Processing,” Small, (in press). https://doi.org/10.1002/smll.202305170

8. J. Rich, B. Cole, T. Li, B. Lu, H. Fu, B. N. Smith, J. Xia, S. Yang, R. Zhong, J. L. Doherty, K. Kaneko, H. Suzuki, Z. Tian, A. D. Franklin, and T. J. Huang, “Aerosol Jet Printing Surface Acoustic Wave Microfluidic Devices,” Microsystems and Nanoengineering, vol. 10, pp. 2, 2024. https://doi.org/10.1038/s41378-023-00606-z

9. B. Huegen, J. L. Doherty, B. N. Smith, and A. D. Franklin, “Role of Electrode Configuration and Morphology in Printed Prothrombin Time Sensors,” Sensors and Actuators B: Chemical, vol. 399, pp. 134785, 2024. https://doi.org/10.1016/j.snb.2023.134785

10. E. G. Franklin, B. N. Smith, and A. D. Franklin, “Impact of NaCl concentration in crystalline nanocellulose for printed ionic dielectrics,” J. Emerging Investigators, vol. 6, pp. 1-5, 2023. https://doi.org/10.59720/22-240

11. S. Lu, B. N. Smith, H. Meikle, M. J. Therien, and A. D. Franklin, “All-Carbon Thin-Film Transistors Using Water-Only Printing,” Nano Letters, vol. 23, pp. 2100-2106, Feb. 2023. https://doi.org/10.1021/acs.nanolett.2c04196

12. R. McNaboe, L. Beardslee, Y. Kong, B. N. Smith, I. Chen, H. F. Posada-Quintero, and K. H. Chon, “Design and Validations of a Multimodal Wearable Device for Simultaneous Collection of Electrocardiogram, Electromyogram, and Electrodermal Activity,” Sensors, vol 22, pp. 8851, Nov. 2022. https://doi.org/10.3390/s22228851

13. B. N. Smith, H. Meikle, J. L. Doherty, S. Lu, G. Tutoni, M. L. Becker, M. J. Therien, and A. D. Franklin, "Ionic dielectrics for fully printed carbon nanotube transistors: Impact of composition and induced stresses," Nanoscale, vol. 14, pp. 16845-16856, Nov. 2022. https://doi.org/10.1039/D2NR04206A

14. A.B.M.H. Talukder, B. Smith, M. Akbulut, F. Dirisaglik, H. Silva, and A. Gokirmak, “Temperature-Dependent Characteristics and Electrostatic Threshold Voltage Tuning of Accumulated Body MOSFETs,” IEEE Transactions on Electron Devices, vol. 69, pp. 4138-4143, Aug. 2022. https://doi.org/10.1109/TED.2022.3184906